Gauge Adjustment:

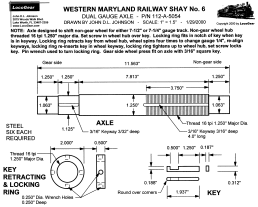

These Shays will be set up for dual gauge (7-1/4", 7-1/2") operation. The method proposed by LocoGear is to have the left hand (non geared) wheel threaded on the axle, driven by a key that can be withdrawn, the wheel rotated to the new gauge and then the key reinserted. Not the simplest method to build but one that should work well.

Here is a variation of the LocoGear method applied to my Climax project. These are 3/4" diameter axles with a large brass hex nut. I plan to use this method on my existing Kozo Shay.

I have used other methods in the past, including steel tires threaded onto the cast iron wheel center. This works well on a rod engine and has the added advantage of increasing adhesion (steel is less slippery than cast iron). The disadvantage is that steel donuts would be required for each wheel.

On an electric GE 44 ton switcher I used an axle with a flange welded/machined to the axle. A 1/4" shim is then inserted between the flange and the wheel. The wheel is a sliding fit on the axle, allowing it to be moved in/out for insertion/removal of the shims. This has worked well. Four 1/4-20 stainless steel bolts hold the wheel to the flange and are inserted from the inside. The ends of the bolts do not show behind the journal boxes. The 44 tonner at 7-1/4" gauge has one side 1/4" off center. This is not noticeable and has never been commented on. So I have no hesitation to having the Shay left hand side 1/4" offset at 7-1/4" gauge. I doubt anyone will notice and it will not affect operation.

Tools & Methods:

A 1-1/4" x 16 tpi tap was acquired via eBay. These normally sell for $120 but one was found on eBay for $9.95. This will make all the internal wheel threads the same size. Axle threads will then be turned on the lathe to match.